Casting Recap

Barrel Alignment

Barrel Exterior

But Weight, There's More

Barrel Liner

Completion and Test Fire

Problem 1: Jamming

Problem 2: Sight Alignment

Problem 3: Unscrewing Barrel

Finishing Up

Conclusion

Appendix 1: Optic

More articles

One Shot Wonder

As with all firearms being tested for the first time after being built, I started by loading a single round into the .22 FAL's magazine. The point of this is so that if a case blows out, the chamber ruptures, or a round slamfires after being fed from the mag, it doesn't cause chain ignition of additional rounds in the magazine.

In this case, none of those things happened. The single round fed from the magazine, fired when I pulled the trigger, and ejected the spent case. It even made a hole somewhere on the target set at seven yards. The sights were off as expected, but functionally things looked good so far. I repeated the single-load test a couple times in case the first good shot had been a fluke, but each test proceeded without catastrophe.

Thus encouraged, I switched to two rounds. Upping the round count by only a single cartridge is intended to test for unintentional full-auto fire in a way that limits the duration of full-auto fire if it happens. It also, as it turns out, tests for jams that happen when there's more than a single round loaded in the magazine.

No matter the number of rounds, the type of ammo, or anything I tried, it was not possible to get the FAL to feed if there was more than a single round in the magazine. Because rounds tend to dip slightly under pressure from the rounds beneath them, jamming on all but a single-loaded round usually indicates something wrong with the feedway, regardless of the type of gun.

Back from the range, side-by-side examination of the dedicated .22 receiver with my custom barrel liner next to a DSA-receiver FAL with the standard kit barrel confirmed the last-round jam theory and revealed the problem.

This was the second dimensional problem introduced by raising the barrel: It also raised the barrel insert relative to the magazine, so rounds were no longer being fed directly into the chamber, but directly into the lower edge of the chamber.

Note lead from bullet strikes on the lower edge of the chamber.

Fixing Feeding

The problem was had been identified, but the solutions were limited:

- Move the magazine up.

- Move the barrel down.

- Make it easier for rounds to get into the chamber given the existing magazine and barrel heights.

Moving the mag up was out of the question; to do so would require reshaping the entire magwell and shifting the ejector block. The amount of welding and reshaping involved would be beyond my capabilities even if I had a welder.

Moving the barrel down (e.g. by unsoldering the insert and making a new one) would just reintroduce the insert jamming problems that necessitated relocating the barrel in the first place. If I tried to work around that by milling off the bottom of the insert so that it fit onto the rails or milled down the rails a bit to fit the insert, the .22 bolt group would sit too high for the chamber insert. Even if I had no instinctive revulsion at the thought of mangling the .22 conversion kit to compensate for my own machining mistakes, it would render it unusable as a drop-in for .308 FALs afterward.

That left the last option: somehow making it easier to get the rounds into the chamber. One obvious approach is to increase the angle of attack so that the cartridges pass over the lower lip of the chamber instead of running into it head-on. Lowering the ejector block or shortening the mag catch would accomplish this, but at the cost of making the magazine misfeed if you pushed on the bottom of it and rocked it back into its error-prone angle. And if the rear of the magazine sat down too far, the bottom of the bolt would be unable to strip rounds out of the feed lips.

Speaking up feed lips, another option is to open up the magazines' feed lips near the front so that rounds sit at a higher angle. When Kurbelgehause heard of my feeding issues, he shared a mechanism for opening up the feed lips; very kind of him when you consider I was using his kit in an unsupported manner. After opening up the feed lips a little bit, cartidges started to feed by hand with slightly higher reliability. I believe that if I'd continued in this manner it probably would have solved the issue on its own, but I was reluctant to continue beyond the point where the magazines could be used with the kit in a standard (read: dimensionally correct) receiver.

Finally I resorted to something that felt like a terrible hack: cutting feed ramps into the chamber extension. Bullets would hit the angled feed ramps and slide into the chamber instead of crashing into a sharp edge. Cutting feed ramps constituted altering the design, but was the only option remaining that didn't break the .22 kit's compatibility with regular FALs.

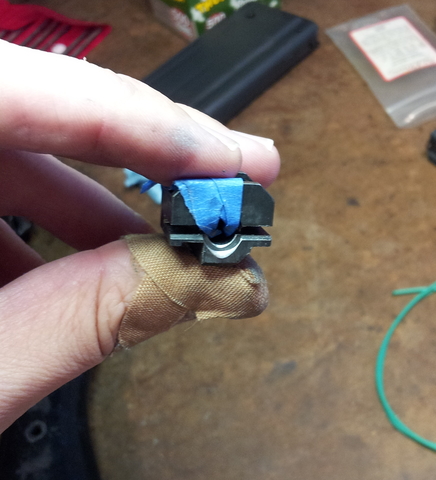

So that's what I did. I used a half-round fine Swiss-cut file to gently introduce feed ramps to the chamber extension, protecting the interior of the chamber with some tape.

There was practically no danger of cutting too far, considering how deep the extractor clearance cuts went. The real problem was getting it symmetrical enough to silence the yammering from my OCD tendencies.

Asymmetry! Fix it fix it fix it fix it fix it fix it...

Between magazine feed lip tweaks and the new feed ramps, hand-cycling rounds now worked perfectly for every cartridge in a full magazine. Now I could take the .22 FAL back to the range to continue the process of confirming function and sighting in.

Or could I?

email: hidi.projects at gmail.com